Buck brings plastic into shape

Injection molding: prototypes and small series

Buck Spritzgussteile Formenbau GmbH is a market-oriented company and both a manufacturer and supplier of high-quality plastic products. Our wide-ranging competencies include all services in the field of injection molding. Already in the development phase supported by us, we are happy to help you with the design of your components. With the courage to innovate, technical know-how and modern processes, custom-made parts are created according to your wishes from the unbreakable material plastic. Individual advice and short decision-making processes are the top priority.

Like a glove:

Our services around the injection molding process

Our experts are at your side from the supporting development to the finishing by means of pad printing to delivery. With technical know-how in the field of injection molding, we bring your ideas into shape. Personal dialogue with the customer is crucial for every project: With Buck, you get an exact impression of what your future plastic idea will look like during the planning phase.

Injection molding in a nutshell

Forward force

From 15 to 400 tons

Material

Numerous plastics such as high-performance thermoplastics, engineering thermoplastics and standard thermoplastics or elastomers

Advantages

High quality at a reasonable cost

Low downtime and downtime due to fast availability

Does your company want to grow?

We grow with you and invest in the latest injection molding processes for you. For example, in 2013 we entered the MuCell® technology and in 2016 we invested in a foaming system for parts for attaching a sealing lip. The production of dimensionally accurate plastic parts is also part of our portfolio.

Injection molding – what is it anyway?

Injection molding is a process that is often used in the processing of plastic. In this process, the material is liquefied and injected into a mold under pressure. In the tool, the material then returns to a solid state. In plastic injection molding, the shape as well as the surface structure of the finished part is determined by the cavity of the clamping unit in the mold.

This technology can be used to produce robust precision parts whose possible applications are particularly diverse: Whether turn signal levers, steering wheel trim, contact carriers or complex sensor technology – Buck injection molded parts are used wherever precision, speed and high quality are required. Our customers are globally active companies, mainly companies in the automotive sector. Through years of experience, our team knows the constantly changing business processes and continuously increasing requirements.

Why injection molding?

Injection molding is an ideal process for processing plastics and producing larger quantities efficiently. Our specialists integrate even complex surface structures directly into the mold. For perfect injection molding, Buck has a very wide range of various plastics available, depending on the requirements.

- Production of recyclable molded parts in large quantities

- Enormous accuracy in a short time expenditure

- Individual surface finishes

- Automated processes ensure reproducibility

- Use of a wide range of materials (thermoplastics and elastomers)

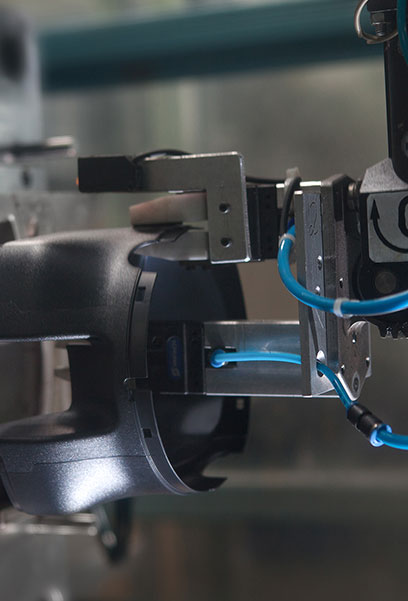

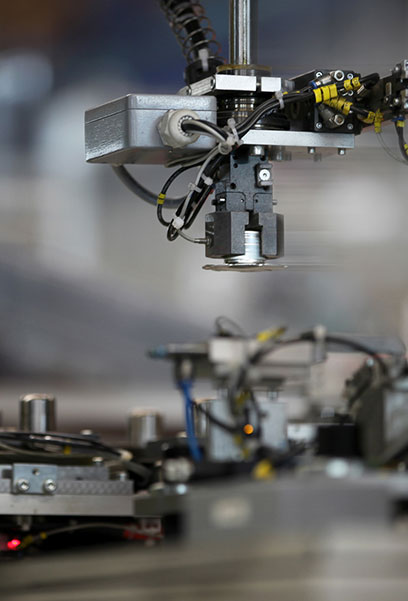

Our Machines

All machines are equipped with MDE (Machine Data Acquisition). In this way, the cost-effectiveness (cycle, good parts, bad parts and the setting parameters) of the current series can be checked at any time during injection molding. Our PPs system (production planning and control system) is in permanent interaction with the MDEs, which means that exceeding the adjustable tolerances (upper or lower limits) can be detected at an early stage and intervened accordingly. In addition, internal pressure sensors in the tool ensure that fluctuations are detected and bad parts are disposed of. The data of the production orders can be retrieved at any time at any workstation.

Simply strong:

modern plastic injection molding made in Germany

We use 50 precision injection molding machines with a clamping force of 15 t to 400 t for fully and semi-automatic production. Buck also manufactures various hybrid components (injected bushings or pins) according to customer requirements using the 2-component and MuCell® process. Our ISO-certified quality management ensures that every single injection molded part meets your high expectations.

Would you like to learn more about our plastic injection molding?

Our team brings your idea into shape: starting with the construction of a prototype, through efficient series production, to on-time delivery.